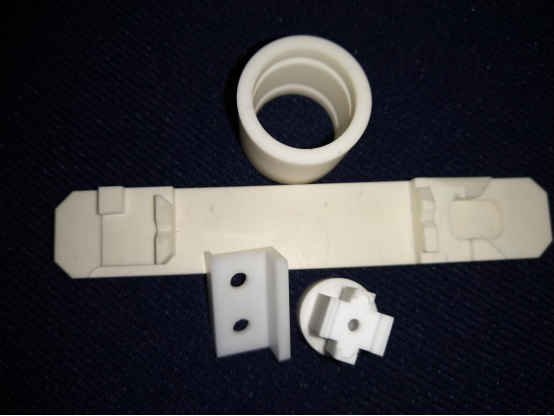

Ceramic plunger, ceramic rod, ceramic tube / ring manufacturer

Focus on alumina ceramic and zirconia ceramic processing customization

WeChat Consulting

Hotline:

Hotline: +86 133-3268-6959

The common application of alumina ceramic materials and alumina ceramics

Alumina ceramics are very wear-resistant precision ceramic materials and are widely used in various industries.

The main forming methods of alumina ceramics are: dry pressing, grouting, extrusion, cold isostatic pressing, injection and casting. Different product shapes, sizes, complex shapes and precision products require different molding methods, and are sintered at high temperature. Alumina ceramic products can only be processed using a diamond grinding process. Alumina ceramic materials have extremely high hardness and wear resistance, high corrosion resistance, high temperature resistance, corrosion resistance and biological inertness. In addition, high temperature sintered alumina can be highly polished and widely used in many fields, such as water valve sheets. And ball valve. Common alumina ceramics have a purity of 90% to 99.7%.

Common applications of alumina ceramics

Ceramic Sealing Parts-Ceramic Valve Seat-Ceramic Mechanical Parts-High Temperature Ceramic Electrical Insulators-Ceramic High Voltage Insulators-Ceramic Electronic Components and Substrates-Bulletproof Armor-Ceramic Rollers and Bearings-Abrasion-resistant or Corrosion-resistant Lining-Ceramic Semiconductor Parts-Laser Cavity- Tray-ceramic blasting nozzle-ceramic microwave components-ceramic frictionless clutch-high temperature cookware and so on.

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it