Ceramic plunger, ceramic rod, ceramic tube / ring manufacturer

Focus on alumina ceramic and zirconia ceramic processing customization

WeChat Consulting

Hotline:

Hotline: +86 133-3268-6959

Precision alumina ceramic sheet is also called precision alumina ceramic lining, high alumina lining, precision alumina ceramic patch, precision alumina lining and so on. So what is the difference between it and ordinary ceramics?

Features of precision alumina ceramics, precision alumina ceramics: First, the hardness is large, its Rockwell hardness can reach HRA80-90; its wear resistance is very good, wear resistance can be higher than manganese steel and high chromium cast iron, can make The service life of the equipment is extended by more than ten times; Furthermore, the precision alumina ceramic sheet is very light and its density is 3.65g / cm, which can greatly reduce the load of the equipment; the precision alumina ceramic sheet is firmly bonded and heat-resistant on the device Good performance, long-term operation without aging at 350 ℃.

What is the difference between precision alumina ceramics and ordinary ceramics?

Why does the precision alumina ceramic plate have such a name? In fact, it is very simple. That is, some components of precision alumina have been added to the ordinary ceramic plate ingredients. The names of the ingredients are shown so that people can better understand the difference between precision alumina ceramics and ordinary ceramics, so that they can better understand the properties of these different ceramic materials, so People can help, so that when you use these different materials, you can distinguish more effectively.

Why is the alumina component specifically added to the ceramic sheet, what is the difference between such a precision alumina ceramic sheet and ordinary ceramics, and what are the different performances? After adding such a precision alumina component, the hardness of the ceramic sheet has been greatly improved, especially this precision alumina ceramic sheet is currently the highest lubricity material, so it is used in the production of many industrial equipment , Has become the best and most practical material, and now it has been fully applied.

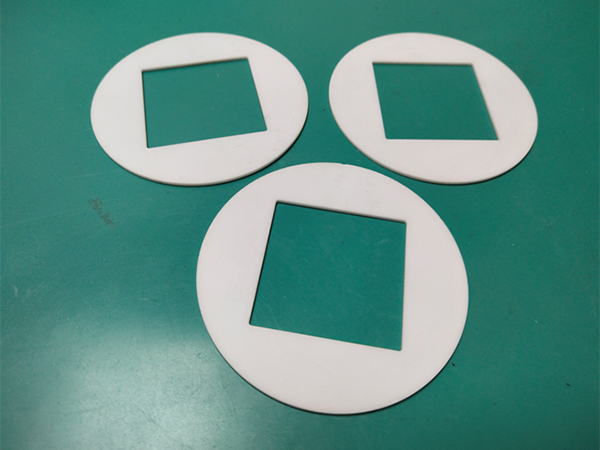

Precision alumina ceramic sheet

The most important point is that compared to ordinary ceramics, precision alumina ceramics are very different in composition and manufacturing process. Ordinary ceramics are processed through raw material preparation, blank forming and kiln firing. Most of the precision alumina ceramics are manufactured by powder sintering.

95 alumina precision ceramic is a kind of alumina precision ceramic. According to the content of alumina in the product can be divided into 99 alumina, 95 alumina and so on. The following introduces 95 alumina precision ceramics by Kezhong Precision Ceramics.

95 alumina precision ceramic skeleton

Alumina precision ceramics are divided into 75 porcelain (75%), 92 porcelain (92%), 95 porcelain (95%), 96 porcelain (96%), 97 porcelain (97%), 99 porcelain (99%), and 995 porcelain (99.5%) and 997 porcelain (99.7%).

Most domestic manufacturers currently produce 95% alumina precision ceramic products. At present, the products have a trend of high content development.

95 alumina precision ceramics is alumina-based material with good chemical resistance and molten metal resistance, high temperature resistance, good finish, thermal stability, small thermal expansion coefficient, good thermal conductivity, high mechanical strength, and insulation High strength, same hardness as corundum, and wear resistance comparable to super-hard alloys.

It can be used for bio-precision ceramics, electronic devices such as high-voltage switch shell insulation materials, mechanical parts such as seal ring valve parts, wear-resistant materials such as wear-resistant precision ceramic balls and rods, high-temperature devices such as high-temperature liquid delivery pipes, etc.

Ultrasound is required for washing. Superior performance, more and more widely used to meet the needs of daily use and special performance.

95 alumina precision ceramic parts

Widely used in lighting appliances, electric heating appliances, petrochemicals, machinery, textiles, automobiles and other industries, the specifications can be customized according to customer needs.

But 95 alumina porcelain is mainly used as corrosion-resistant and wear-resistant parts. In addition, 95 alumina precision ceramic materials perform well. In terms of mechanical properties, mechanical properties refer to the ability of a material to not be damaged under the action of mechanical forces. Generally, tensile strength, flexural strength, and compressive strength are divided according to the direction of the force, the direction of the force, and the point of the force.

The tensile strength of 95 alumina precision ceramics is generally above 160Mpa, which is usually greater than the best sealing strength.

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it