Ceramic plunger, ceramic rod, ceramic tube / ring manufacturer

Focus on alumina ceramic and zirconia ceramic processing customization

WeChat Consulting

Hotline:

Hotline: +86 133-3268-6959

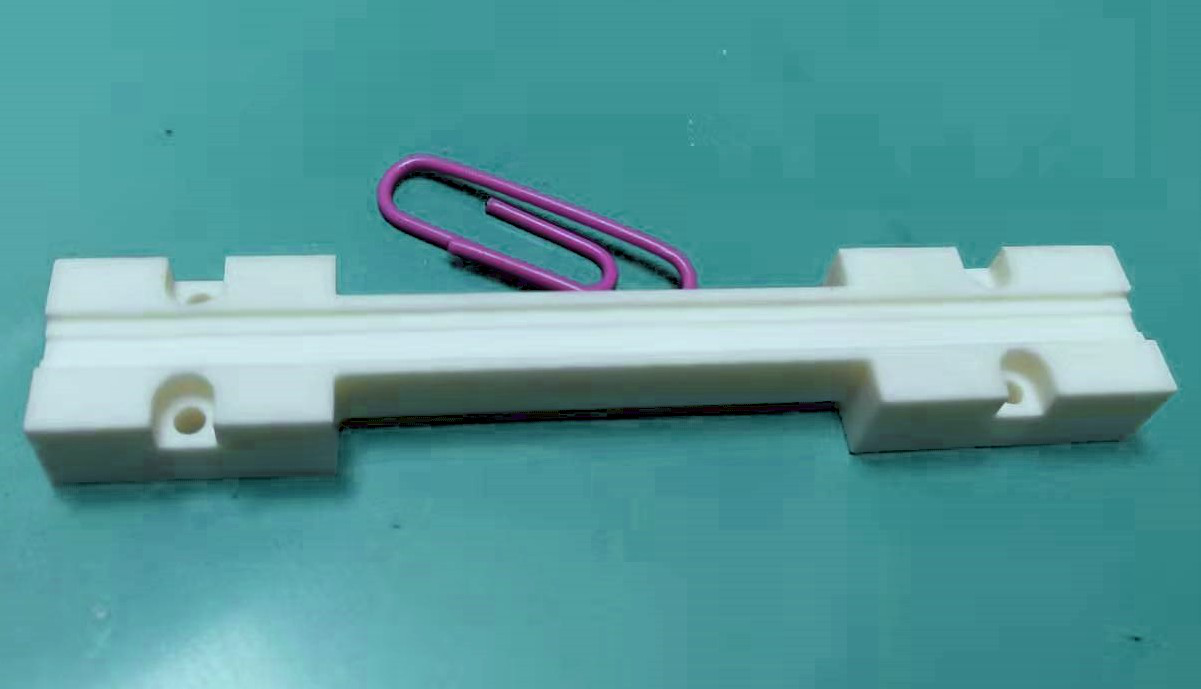

Zirconia ceramic structure has a higher surface finish, is mirror-like, extremely smooth, and has less friction with the net, which can further increase the life of the net, greatly reduce the net consumption, reduce the current of the net portion of the paper and reduce power . In addition, the toughness of zirconia ceramic structural parts is excellent, which overcomes the inherent brittleness of the ceramic itself, has higher wear resistance, greatly prolongs the service life of the product, and significantly improves the paper quality.

Ceramic toughness comparison:

The toughness of zirconia ceramics is 4 times that of alumina ceramics. At the same time, zirconia is freely dropped from a height of one meter, but there will be some gaps.

Density comparison:

Zirconia ceramics are twice as dense as alumina ceramics.

Density comparison:

The density of zirconia ceramic structural parts is higher than that of alumina ceramics. The density of alumina ceramics is 3.5. The density of zirconia ceramics is 6. The texture is more delicate. Above 9, it is mirror-like, extremely smooth, and has a smaller friction coefficient.

Comparison of surface finish:

Zirconia ceramic structural part is a very important structural ceramic newly developed next to alumina ceramics. Because of some of its good properties (such as its fracture toughness higher than alumina ceramics), zirconia ceramic structural parts are receiving more and more attention.

Release time: 2019.12.13 Source: Mingjue Ceramics Website: www.mingjuetaoci.com

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it