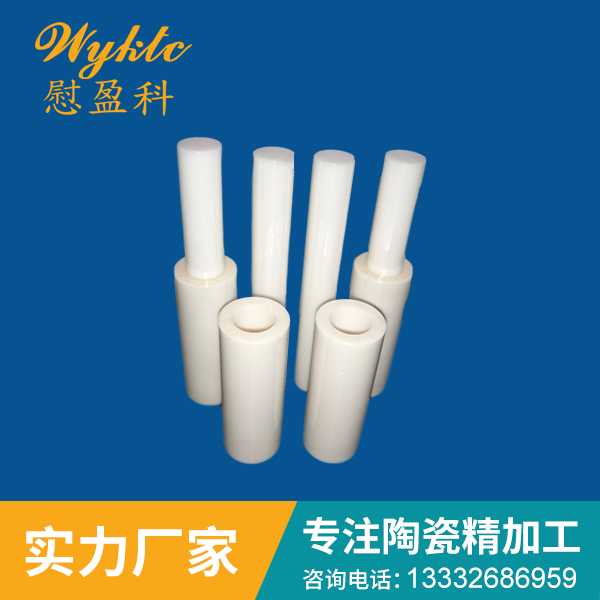

Ceramic plunger, ceramic rod, ceramic tube / ring manufacturer

Focus on alumina ceramic and zirconia ceramic processing customization

WeChat Consulting

Hotline:

Hotline: +86 133-3268-6959

Alumina Wearable Porcelain : 1. High hardness

The Rockwell as determined by the Shanghai Institute of Ceramics, Chinese Academy of Sciences HRA80-90 The hardness is second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel.

Features:

2. Good wear resistance

As measured by the Powder Metallurgy Research Institute of Zhongnan Polytechnic University, its wear resistance is equivalent to 266 times of manganese steel and

light weight having a density of 3.5g / cm3, only half of steel, can greatly reduce the equipment load.

99 alumina ceramic sheets

4. Wide application scope

Alumina Ceramic is a very wear-resistant precision ceramic material, which is widely used in electronics, steel, smelting, machinery, coal, mining, chemical, Medical, military, aerospace, photovoltaic semiconductors, etc., all enterprises with large wear and tear on mechanical equipment can choose different types of products according to different needs.

The main forming methods of alumina ceramic products are dry pressing, grouting, extrusion, cold isostatic pressing, injection and casting, different product shapes, sizes, complex Products with modeling and precision require different molding methods. The purity of common alumina ceramics is 90% to 99.7%.

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it