Ceramic dispensing valve: the dispensing valve is composed of the air cylinder, valve body and the gel outlet. The air cylinder and valve body are separated by diaphragm to avoid the glue invading the air chamber. The valve in the gel outlet body is fixed on the piston rod, and the valve switch is used to open and close the glue. So, why does dispensing machine use ceramic dispensing valve?

Working principle of dispensing valve: compressed air is sent into the rubber bottle (syringe), and the rubber is pressed into the feed pipe connected with the piston chamber. When the piston is in the up stroke, the piston chamber is filled with rubber. When the piston pushes the rubber dropping needle downward, the rubber is pressed out from the needle mouth. The amount of glue dripped is determined by the distance of the piston down stroke, which can be adjusted manually or controlled in the software.

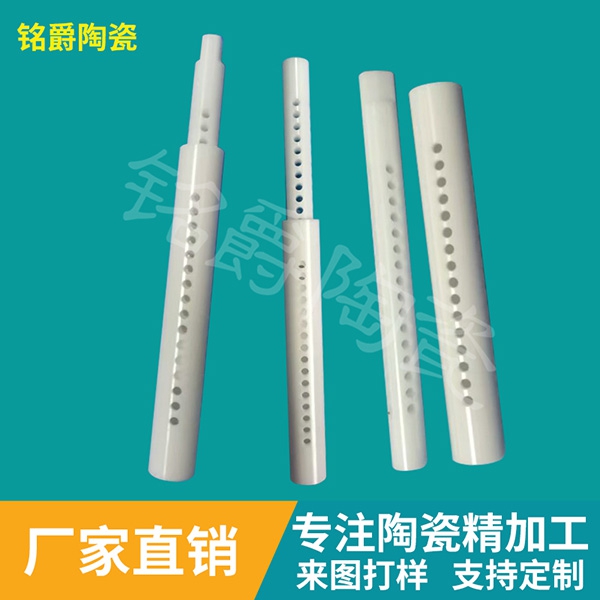

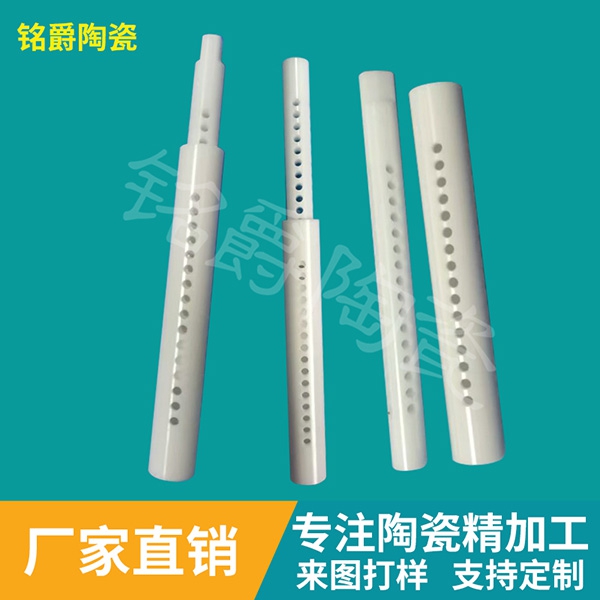

Leakage of rubber valve: leakage of rubber valve often occurs in traditional dispensing valve, which is caused by too small diameter of needle. The metal dispensing valve is not resistant to high temperature, easy to paste colloidal liquid, and even affect the action of exhaust bubble. Ceramic dispensing valve can perfectly solve the problem of glue leakage. Ceramic dispensing valve produces the least back pressure and the most smooth flow of liquid.

Inconsistent size of glue: when the size of glue is inconsistent, it is mainly caused by the unstable pressure of the pressure cylinder or air storing fluid. The inlet pressure regulator shall be set at 10 to 15 psi below the minimum in plant pressure. The pressure used for the pressure cylinder shall be higher than the middle of the pressure regulating gauge, and the low pressure part of the pressure gauge shall be avoided. The control pressure of ceramic dispensing valve is at least 60 psi, which can ensure the stability of dispensing, and the ceramic dispensing valve is resistant to high temperature and corrosion, and will not form the flow blockage of glue liquid.

Flow rate is too slow: the flow rate of dispensing valve is too slow, which is also caused by the material of metal dispensing valve itself. If the metal temperature is too high, the liquid will stay out of date and agglomerate, thus forming a blockage, and the flow rate will correspondingly slow down, resulting in the inconsistent size of the glue. The ceramic dispensing valve made of zirconia ceramic can solve this problem perfectly. The zirconia ceramic has the characteristics of wear resistance and high temperature resistance. Even under the high temperature of 1400C, it can ensure the normal flow of liquid.

Liquid drying in the valve: this situation is mainly due to excessive moisture or reuse of instant glue. The metal dispensing valve will cause the temperature of the valve body to become cold because of the use environment, while the ceramic dispensing valve can ensure the constant temperature state, and when the liquid flows through the valve body, it will not dry up to ensure the normal flow.

Hotline:

Hotline:

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it