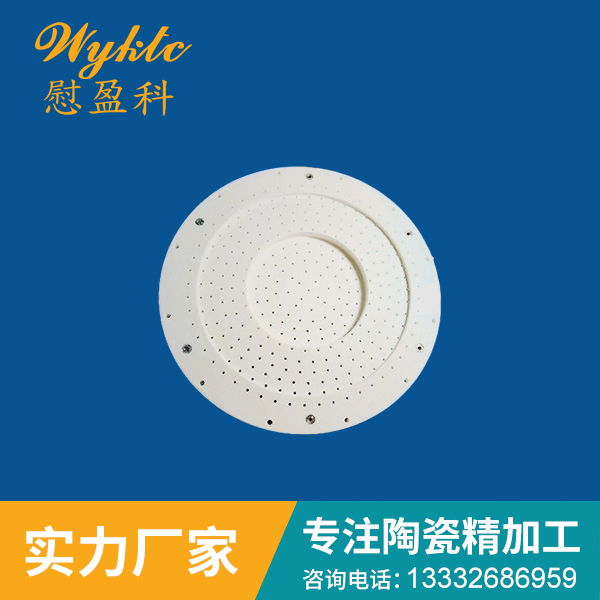

Ceramic plunger, ceramic rod, ceramic tube / ring manufacturer

Focus on alumina ceramic and zirconia ceramic processing customization

WeChat Consulting

Hotline:

Hotline: +86 133-3268-6959

Zirconia ceramics have proved to be reliable in industrial, medical and other fields. Abstract: In many industrial fields and medical fields, this new ceramic material has been widely used. Zirconia ceramics, as a part of modern consumer electronics industry, have development potential. Future.

In many industrial fields and medical fields, this new ceramic material has been widely used. Zirconia ceramics, as a part of modern consumer electronics industry, has a promising future.

How critical is the organic chemical tempering treatment of zirconia ceramics? Let me make a simple description below. Before zirconia ceramics have not undergone organic chemical tempering treatment, it means that they are like an unqualified person and are very prone to common failures. Only after undergoing organic chemical tempering treatment of zirconia ceramics, its characteristics will be more stable, not easy to crack under the condition of high temperature, and improve the compressive capacity of zirconia ceramics.

Zirconia ceramic is reliable because of its heat resistance, solvent corrosion resistance, oxidation resistance, wear resistance, large linear expansion coefficient, small constant pressure specific heat and heat transfer coefficient, and toughening characteristics after anti-aging. It has become a key raw material that cannot be ignored in the refractory and thermal insulation material manufacturing industry and the special ceramics industry.

The foam ceramics made of zirconia ceramics can be used for nickel-based alloys. The foam ceramics are used for molten steel rolling and obtain excellent cleaning results. Reasonably remove non-metallic materials.

As a component of consumer electronics, porcelain has a strong vitality. It is very targeted at zirconia ceramics. It has been proven to be a raw material for components in many fields such as optical fiber communication, industrial production, and diagnosis and treatment. It has entered the consumer electronics industry, but it is a result of its reduced cost and improved ductility. .

In terms of strength, the hardness of zirconia ceramic is around 8.5, which is very close to the hardness of emerald 9, while the hardness of polycarbonate is only 3.0, the hardness of tempered laminated glass is 5.5, the hardness of titanium magnesium aluminum alloy is 6.0, and the hardness of Corning glass Is 7.0.

Contact: Miss Li / +86 13332686959

Contact: Miss Li / +86 13332686959 Contact: Mr Li / +86 13316634021

Contact: Mr Li / +86 13316634021

Consultant: Mr. Lin / 13532935121

Consultant: Mr. Lin / 13532935121

Mail Box: 29384242801@qq.com

Mail Box: 29384242801@qq.com

Fax: +86 0769-81587969

Fax: +86 0769-81587969

Website: en.dgmjtc.com

Website: en.dgmjtc.com

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town,

Add: No. 9, Xingfa South Road, Chang'an, Wusha Community, Chang'an Town, Scan it

Scan it